| Klischograph K 151 (1951) | ||||||||||

|

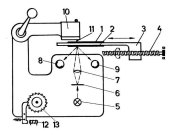

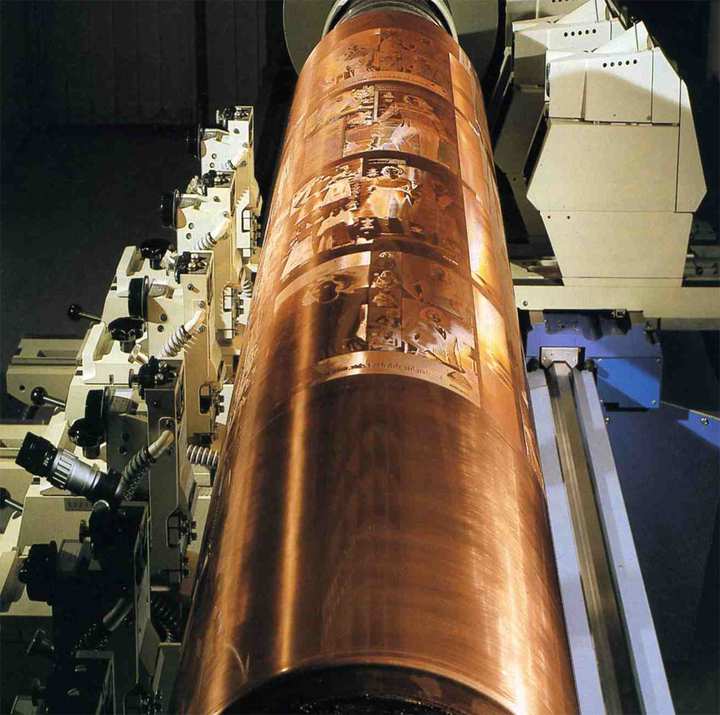

The Klischograph scans a picture line by line, and the resulting scan signal is used to control a steel stylus, which engraves more or less deep cuts into the surface of a printing plate, depending on the grey tone value of the pixel being scanned. The material of the printing plate can be either plastic or metal. This results in a screened printing plate for letterpress printing or for gravure printing.

Klischograph K 151 Catalogue 1959 (German) "für uns alle" No. 2 , 1971, page no. 3 (German)

Catalogue: (Englisch)

Wirtschaftlich denken Think economicallyElektronisch gravieren Engrave electronically

Rationell setzen Set rationally

|

||||||||||

| The material to be engraved is mounted on a table, which moves back and forth under the engraving stylus. The picture original is mounted on the bottom side of the same table, and is scanned from below. This makes the engraved picture on the printing plate automatically wrong-reading, as required for the printing process. The original picture must have the size in which it shall be printed. | ||||||||||

|

Operating manual

|

||||||||||

|

|

||||||||||

|

(written and produced by Hell employees)

|

||||||||||

|

|

||||||||||

|

||||||||||

|

||||||||||